Laboratory of Macrokinetics of Solid State Reactions

The Laboratory has been organized in March 1982 on the basis of the scientific group "Kinetics and Thermodynamics of SHS processes" (since 1977). Until 2021, the Laboratory was named "Laboratory of Kinetics of SHS Processes".

The total number of employees – 15, of which: Dr. Sci. – 1, Ph.D. – 7, MS – 6, Engineer – 1.

The Main Area of Scientific Activity

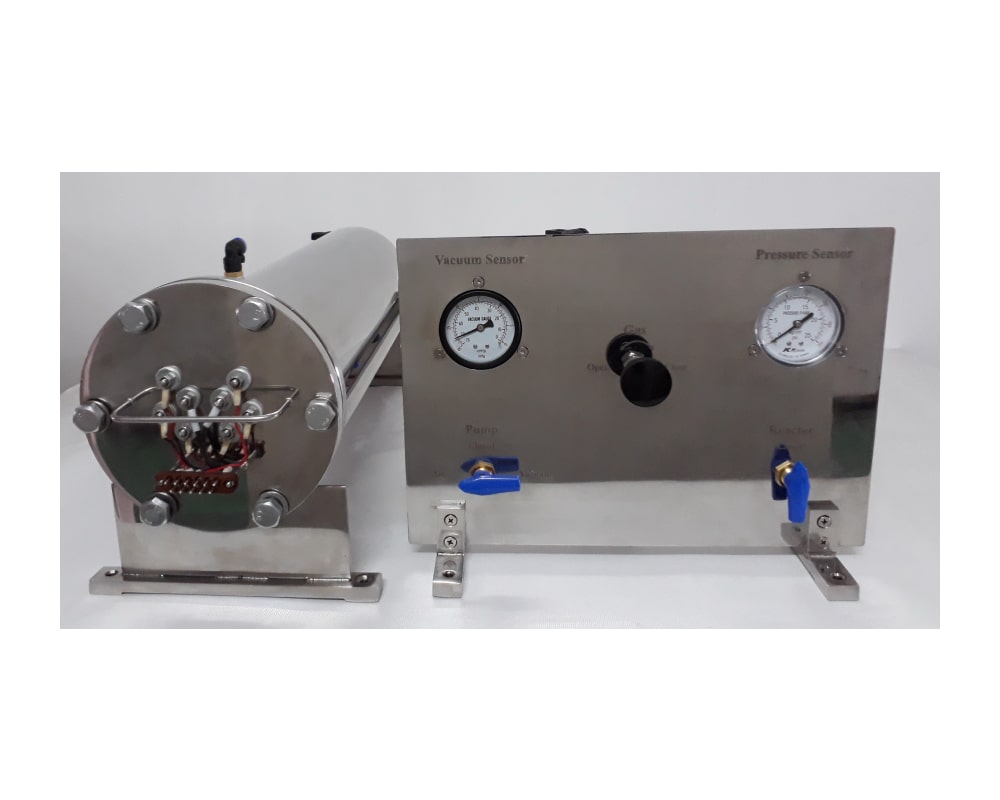

- Synthesis of metals and alloys, ceramic, and composite materials by the novel combustion synthesis (CS) or self-propagating high-temperature synthesis (SHS) method with chemical stimulation and/or by thermo-kinetic coupling of reactions.

- Solution combustion synthesis (SCS) of nanomaterials: metals, alloys, oxides and oxygen-free ceramics.

- Kinetics and mechanism of high temperature rapid solid-state reactions at strongly isothermal and non-isothermal conditions.

- Theory of reactive diffusion.