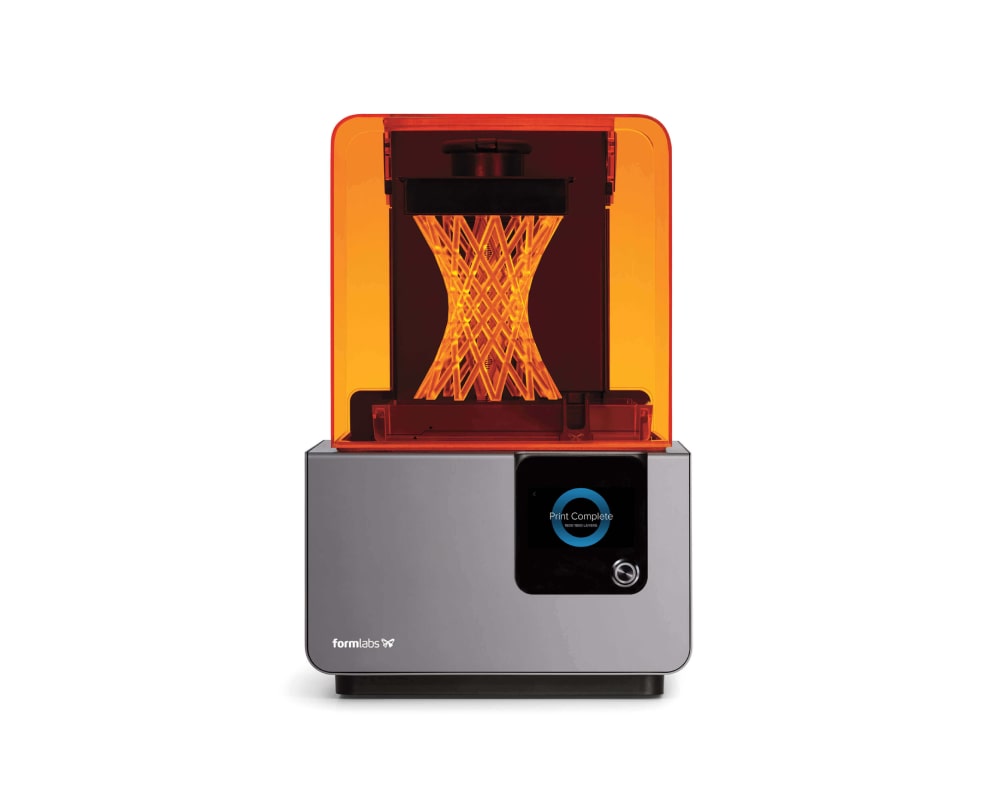

3D printing research lab

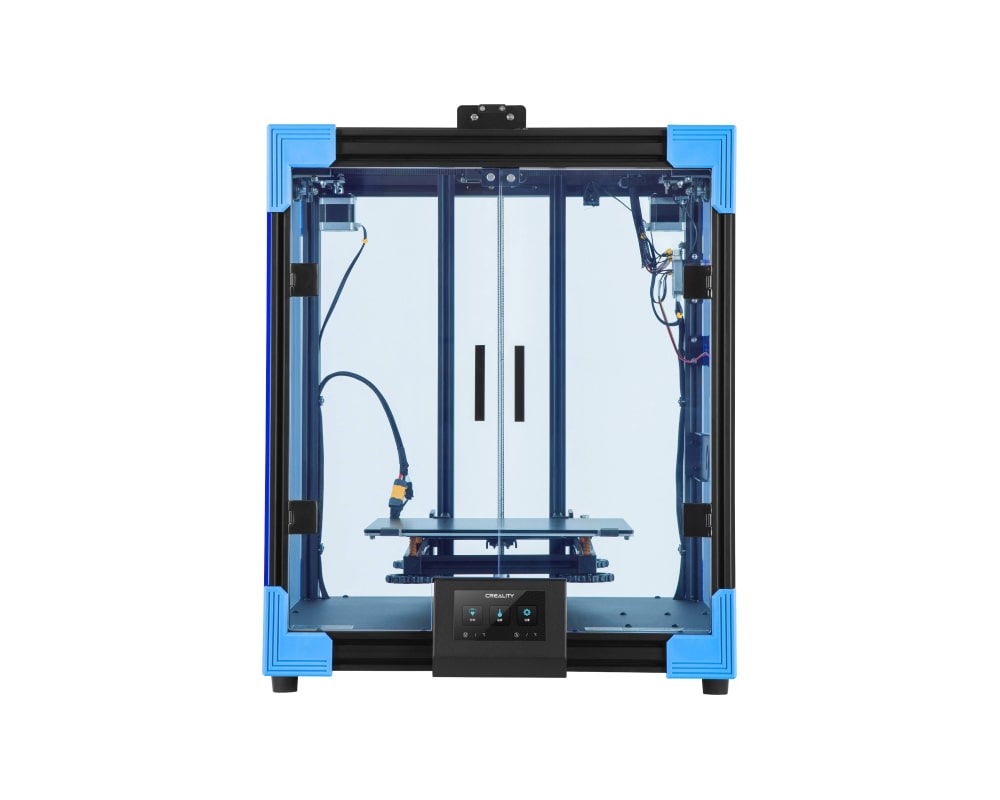

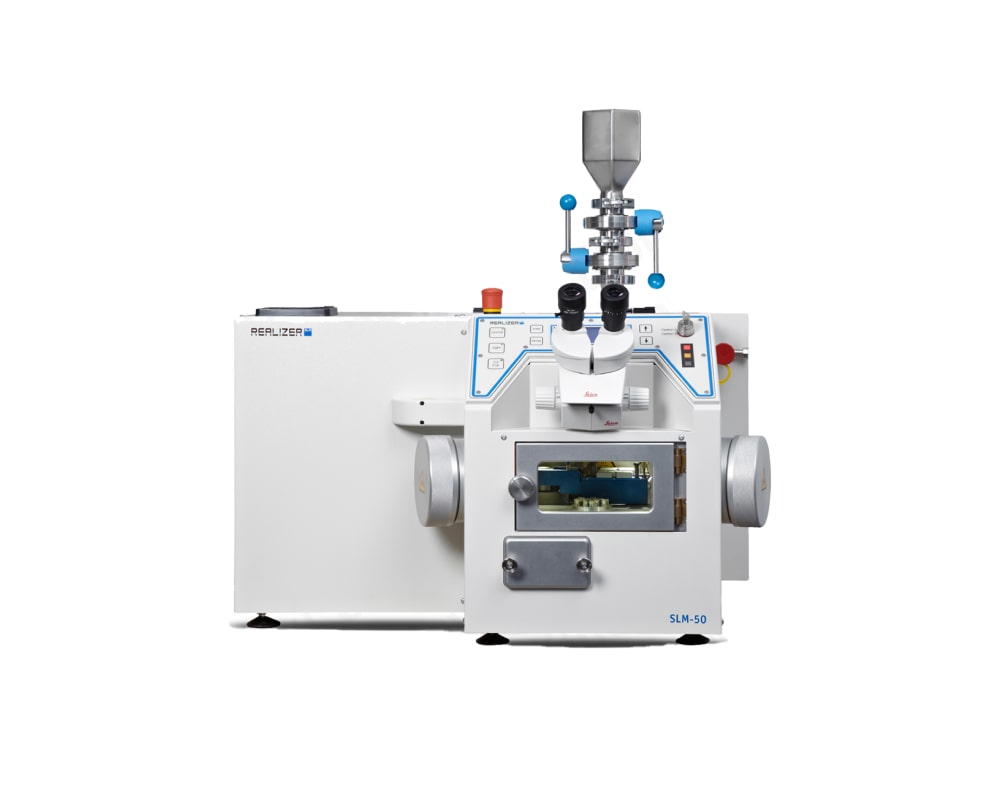

The main goal of the group is the additive manufacturing of sintering of biocompatible, biodegradable materials, and investigation of their properties. Such implants are used for the manufacturing of the next generation implants. The group investigates the manufacturing process, sintering mechanism, and the influence of the sintering conditions on the process, including th laser current intensity, layer thickness, point distance, sintering energy and distribution of the energy.

The group studies the mechnical and physical properties of the as manufactured implants, their hardness, stiffness, flexural strength, comprossive strength, Young’s modulus, open and close pososity, piezoelectricity and thermal properties.

Additive Manufacturing technology development: There are limited number of ceramic materials which are possible to manufacture by additive technology. The group develops bioceramic composites to manufacture biodegradable bioactive implants for bone regeneration.