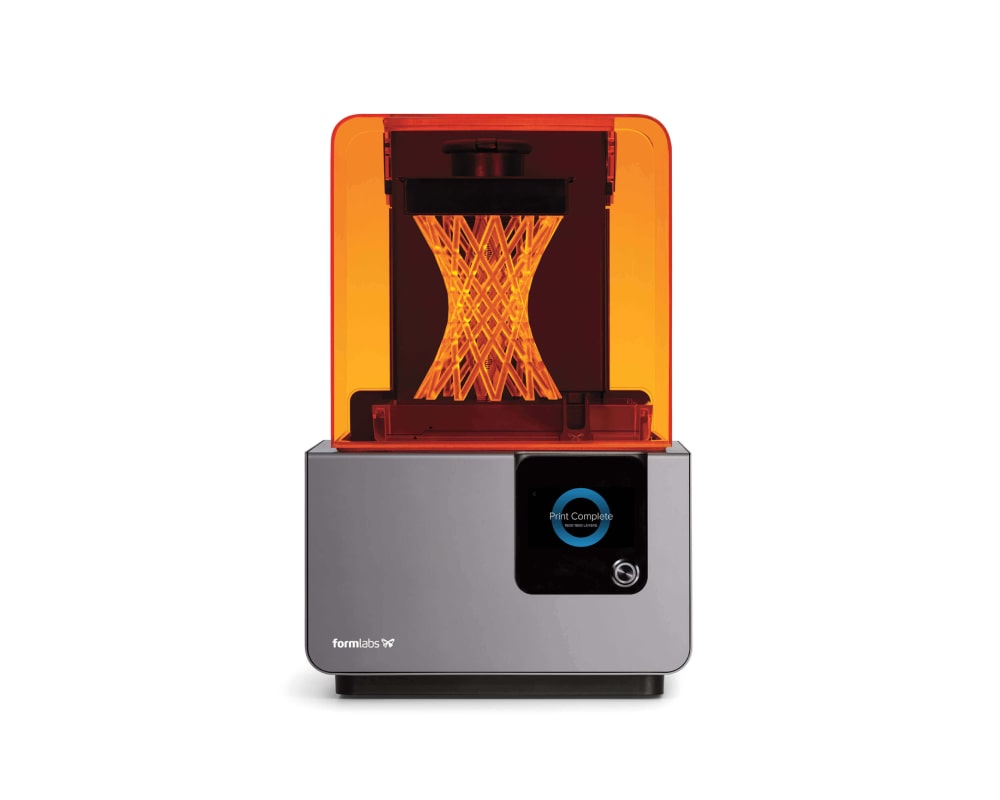

Stereolithography (SLA) 3D Print

Stereolithography belongs to a family of additive manufacturing technologies known as vat photopolymerization, commonly known as resin 3D printing. These machines are all built around the same principle, using a light source a laser or projector to cure liquid resin into hardened plastic. The main physical differentiation lies in the arrangement of the core components, such as the light source, the build platform, and the resin tank.

SLA 3D printers use light-reactive thermoset materials called “resin.” When SLA resins are exposed to certain wavelengths of light, short molecular chains join together, polymerizing monomers and oligomers into solidified rigid or flexible geometries.

SLA parts have the highest resolution and accuracy, the sharpest details, and the smoothest surface finishes of all 3D printing technologies, but the main benefit of the stereolithography lies in its versatility.

Material manufacturers have created innovative SLA resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

Advancements in 3D printing continue to change the way businesses approach prototyping and production. As the technology becomes more accessible and affordable and hardware and materials advance to match market opportunities and demands, designers, engineers, and beyond are integrating 3D printing into workflows across development cycles. Across industries, 3D printing is helping professionals cut outsourcing costs, iterate faster, optimize production processes, and even unlock entirely new business models.

Stereolithography 3D printing in particular has undergone significant changes. Traditionally, SLA 3D printers have been monolithic and cost-prohibitive, requiring skilled technicians and costly service contracts. Today, small format desktop printers produce industrial-quality output, at substantially more affordable price points and with unmatched versatility.